Mark-10 Force Gauge Grips and Attachments

Grips and attachments are essential components of test systems, designed for a range of tension, compression, and torque applications. Our grips and attachments are able to mount to force gauges, torque gauges, sensors, and test stands. Eye end adapters may be used with some gauges and sensors to make it fast and easy to change fixtures. Contact us now to help select the ideal grip for your application.

Wedge Grip

General tensile testing

Capacities up to 2000 lbf / 1000 kgf / 10 kN

Miniature Wedge Grip

100 lb [500 N] capacity

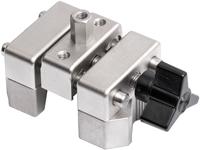

Mini Component Grip

For a variety of pull-off tests

30 lb capacity

Multi-jaw Grip

Capacity 100 lb

For gripping round and irregularly shaped items

Secures a spring, chain, or other sample during tensile testing

500 lbF capacity

High Capacity Clevis Grip

Designed for various pull testing applications, including extension spring testing, chain link break force testing, and other applications.

2000 lb capacity

Ribbon Wrap Grip for textile webbing, tape and braided materials

For compliance to ASTM D6775 when tensile testing

Capacity: 2000 lbs

Film & Paper Grip

Tensile testing of film, paper, and other thin materials

100 lb capacity

Miniature Film & Paper Peel Grip

Capacity of 50 lbF (250 N)

Pneumatic Film & Paper Grip

Tensile testing of film, paper, and other thin materials

100 lb capacity

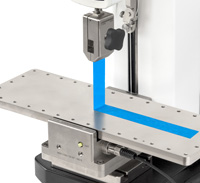

90° Peel Test Fixture for testing according to ASTM D6862, D3330, D903, model G1109

Coefficient Of Friction Fixture

TAPPI T829 Score Quality Bending Fixture

Opening Force Fixture

Extraction / pull force testing of cork stoppers

Conforms to ISO 9727

Accommodates up to 1.5 L bottles

200 lbF (1 kN) capacity

ASTM D6195 Loop Tack Fixture

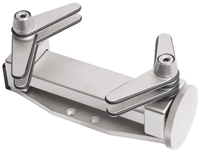

Flip Cap Pull Grip

Spring loaded hook engages the cap’s tab

20 lbF (100 N) capacity

Parallel Jaw Grip

General tensile testing

200 lb capacity

Parallel Jaw Grip, Medium

General tensile testing

Eye end mounting

Max. sample thickness: 1.27 in (32.3 mm)

Extended jaw lengths available

200 lbF (1 kN) capacity

Parallel Jaw Grip, Large

General tensile testing

Eye end mounting

Max. sample thickness: 1.34 in (34.0 mm)

Extended jaw lengths available

2,000 lbF (9 kN) capacity

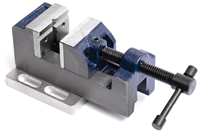

Vise Grip

General tension compression testing

G1106 Self-centering Vise Grip

For samples up to 2"/50mm

Capacity 500 lbF (2,500 N)

Wire Terminal Grip

Pull testing of wire and tube terminals/crimps, and other slender samples

200 lb capacity

Wire Terminal Grip

200 lb capacity

High Capacity Wire Terminal Grip

2000 lb capacity

Dual Roller Cam Grip

Pull testing of wires, tubes, and other slender samples

200 lb capacity

Adjustable Dual Roller Grips

Pull testing of wire and tube terminals

Wide range of groove widths

200 lb capacity

Wire and Filament Grip

Testing of small diameter wire and filaments

50 lbF capacity

Wire / Rope Grip,

Bollard Style, Medium

Pull testing of wire, rope, and yarn

Max. sample size: ⌀0.26 in (6.6 mm)

Integrated eye end

200 lbF (1 kN) capacity

Wire / Rope Grip, Bollard Style, Large

Pull testing of wire, rope, and yarn

Max. sample size: ⌀0.21 in (5.3 mm)

Integrated eye end

1,000 lbF (5 kN) capacity

High Capactiy Wire/Rope Grip

2000 lb capacity

Eccentric Roller Grip

2000 lb capacity

Compression Plates

High Capacity Compression Plates

This family of bend fixtures is designed for 3-point and 4-point bend testing of plastics, metals, ceramics, tubing, and many other materials.

Bases feature movable blocks with multiple V-grooves to accept several roller diameters. 10 mm dia. rollers are included, and other sizes are available.

500 lbF and 2,0000 lbF capacities available.

Jacobs Chuck Grip (Force)

Secures a fixture or sample during tensile testing

30 lb capacity

Padded Attachments

Padded attachments for ergonomics analysis and job task analysis

500 lb capacity

Rubber Tip

Simulates a human finger in compression testing

50 lb capacity

Syringe Compression Fixture

Conforms to ISO 7886-1

100 lbF (500 N) capacity

Bottle / Round Sample Grip

Torque and top-load testing of closures, bottles

100 lbin capacity

Cap Grip

Secures bottle caps during torque testing

100 lbin capacity

Secures bottle caps with movable gripping posts for torque or pull testing

Accommodated Cap Diameters of 0.2 - 3.5" (5.1 - 89.0 mm)

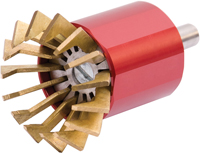

Jacobs Chuck Grips For TSTM

Secures a fixture or sample during torque testing

100 lbin capacity

Hooks

These hooks are ideal for a variety of tensile tests

Capacities up to 1,000 lb

Snap Hook

Capacity 500 lbF [2,500 N]

ASTM D5748 Puncture Fixture

For determining the puncture resistance of plastic films and other materials

For use with test stands ESM750 and ESM1500

Puncture Fixture for testing gypsum board

Flat Heads

These attachments are ideal for compression testing of buttons, membrane switches, etc

200 lb / 500 lb capacity

Extension Rods

For use between a force gauge and another attachment or grip

200 lb / 500 lb capacity

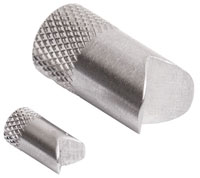

Chisel Points

For compressing or puncturing a variety of samples

200 lb / 500 lb capacity

Cone Points

For puncturing a variety of samples

200 lb / 500 lb capacity

V-grooves

For compression testing of round or odd shaped samples

200 lb / 500 lb capacity

Swivel Adapters

Swiveling adapter, for use between gripping fixtures

200 lb / 500 lb capacity

Typical applications include the testing of adhesives, films, and packaging, such as foil seals found on yogurt containers, juice containers, and others.

Maintains 90° angle between the table and the direction of pull

Maximum table travel: 8.2 in (210 mm)

Button Puller

Capacity 30lbs

Connect force gauges and attachments with different thread sizes. Use them with a force gauge and a test stand to create a complete testing system.

Prevent Grip Rotation

Quick grip installation and removal

Mount to common load cells, test frames, and force gauges

Individual adapters and kits available

Series STH Attachments

Secures fixtures, bits, or samples during torque testing

100 lbin capacity

Hi / lo limits indicator

Indicates pass or fail condition during a test

Compatible with force gauges and torque gauges with set point outputs

Set Point Cable

Stops / reverses motorized test stand at load set points

Sends a set point signal to an external device

Axial Displacement Compensator

Adapt common strain gage-based load cells and torque sensors to the 5i and 3i indicators

Programmable via via USB/RS-232 through the indicator

Permit inline pull testing with a force gauge 500 lbF (2.5 kN) capacity

Inline Adapters for Force Gauges

WT3002 - Ring Terminal Fixture Insert for WT3 and G1076

Compression Plate, Self Leveling

Self-aligning compression plate adjusts to the angle of the sample