If you are rigging towers, guy wires, overhead lines, zip lines, guard rails or architectural cables line tension is critical to ensure safety and correct operation. There are 2 common techniques for measuring the inline tension;

The first method is to use a cable tension meter like our CTM2 or CBM CableBull models. These tension meters use a 3 roller system where the cable passes under the outer rollers and over a center roller imparting a perpendicular force on the center roller which is connected to a load cell. The force is displayed in lbf (pounds force), kgf (kilograms force) or N (Newtons) on a digital display. The CTM2 needs to be calibrated in advance for each cable diameter and wire construction. The advantage of the CBM is that it does not need to be precablibrated, it can measure an 8-10mm range of cable diameters. It also features and unique design that allows for a very small wrap angle providing an accuracy of ± 1% of Full Scale or better. Both tension meters allow the operator to quickly measure and adjust the tension in real-time without disconnecting the cables.

CBM CableBull

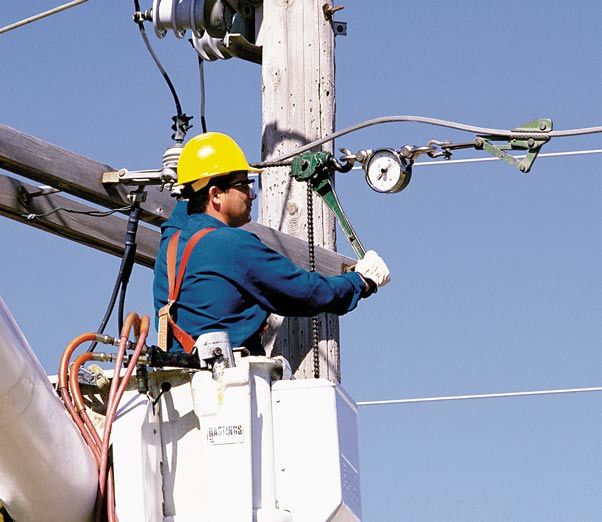

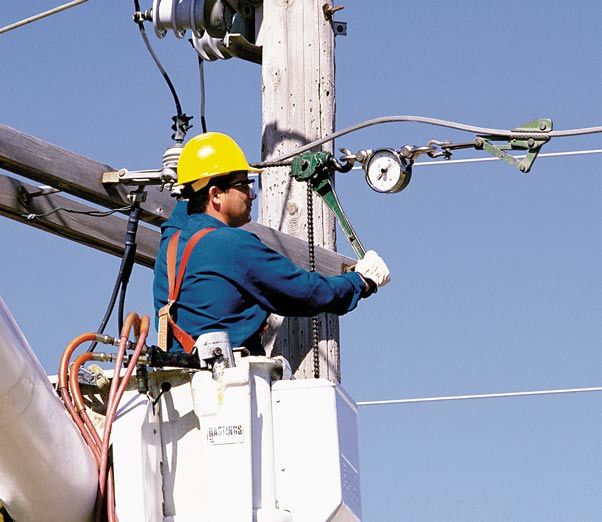

The second method for measuring line tension of a fixed span cable is to use an inline dynamometer like our AP model. A dynamometer measures in-line force or tension by means of a load cell or mechanical scale installed between two shackles or hooks. Typically the dynamometer is attached to a ratcheting cable puller on one end and a come-a-long on the other, allowing the cable to tightened while in place as shown in the picture below.

Lineman tensioning cables with an AP5 Dynamometer

The advantage of the dynamometer is it doesn’t need special calibration and the cost is lower then the tension meter. The negatives are that you may need to disconnect the cable to insert the dynamometer or it requires special rigging equipment to leave it in place which also lowers the accuracy. We also offer digital dynamometers.

At Checkline.com we offer a wide range of equipment to measure inline tension and force of cables and much more. Please contact us today to review your application. We are happy to help you find the ideal test equipment for your unique application.