Tension meter for continuous measuring low and high tensions of textile ribbons, films, foils, fiber bunches etc.

Tape rollers mounted on both sides, width of the cylindrical rollers from 15 mm up to 100 mm with tension ranges from 0-500 g up to 100Kg.

Other roller materials (Nickel-plated steel or Plastic), as well as surface coatings, e. g. anti adhesive coatings (Code AH), Carbon-Optimized Coatings are optional

- Dual-flanged outer guide rollers with various widths from 10 mm up to 100 mm

-

Various output signals:

• analog (0-1V DC)

• RS232 (optional)

• 0-10V DC (optional) - Cylindrical tape roller, ball-bearing mounted

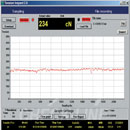

- Integrated measuring amplifier

- Easy calibration to customized material by operator

- Rugged aluminum housing

- Optionally available: Inspection Certificate 3.1 according EN 10204 with calibration report

- Optional hand-wheel feature to open/close roller system for easy threading of material

| Model | Range | Roller Width (mm) |

|---|---|---|

| TSB2-500 | 0 - 500 g | 20, 30, 36, 41, 50, 100 |

| TSB2-1000 | 0 - 1000 g | 20, 30, 36, 41, 50, 100 |

| TSB2-2000 | 0-2000 g | 20, 30, 36, 41, 50, 100 |

| TSB2-5000 | 0-5000 g | 20, 30, 36, 41, 50, 100 |

| TSB2-10K | 0-10 Kg | 15, 20, 30, 36, 41, 50, 100 |

| TSB2-20K | 0-20 Kg | 15, 20, 30, 36, 41, 50, 100 |

| TSB2-50K | 0-50 Kg | 15, 20, 30, 36, 41, 50, 100 |

| TSB2-100K | 0-100 Kg | 15, 20, 30, 36, 41, 50, 100** |

Important for your order: Please specify model and roller width!

Small dual-flanged outer guide rollers are standard. All 3 rollers can be equipped with one flange, if the material to be measured is wider than the rollers. Please request when you order.

Calibration to customized material: If process material differs significantly from the Electromatic calibration material in diameter, rigidity or shape, special calibration using customer supplied samples is recommended. For this purpose a material sample of about 5 m should be supplied.

| Accuracy | ±1 % full scale ±1 digit other calibration material: ±3 % full scale or better |

| Overload protection | 100% of tension range |

| Measuring principle | Strain guage bridge |

| Measuring roller deflection | Max. 0.5 mm |

| Natural frequency | Approx. 500 Hz, depending on tension range |

| Temperature drift | less than ±0.05 % fullscale/ºC |

| Output signal | 0 - 1 V DC (analog) |

| Damping | 30 Hz |

| Temperature range | 10 - 45 ºC |

| Air humidity | 85 % RH, max. |

| Power supply | +12 - 24 V DC, max. 50 mA regulated |