EPS is a control dancer and used for closed-loop tension control on winding of endless material. It is a considered and "active" dancer control system.

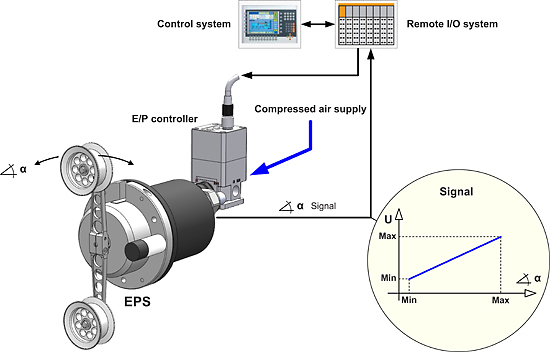

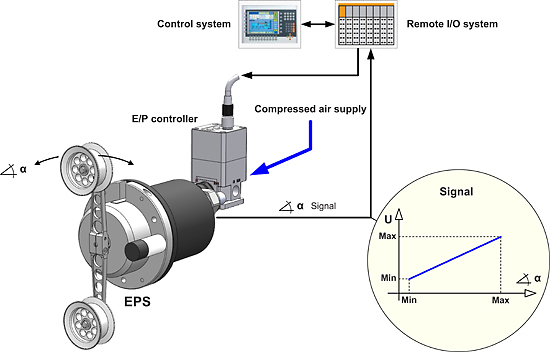

EPS is operated as an electrically controlled P/F actuator providing a large range of adjustment for the user-set desired tension level.

The position of the dancer is measured by means of a rotary encoder, giving a standard output signal specially-designed to be able to maintain precise tension control even under high-dynamic speed variations.

The position of the dancer is measured by means of a rotary encoder, giving a standard output signal specially-designed to be able to maintain precise tension control even under high-dynamic speed variations.

- Wide adjustable tension range

- Superb start/stop performance characteristics

- Compact design requires minimal space for mounting

- Maintains precise tension control even under high-dynamic speed variations

- Extremely robust design is maintenance-free

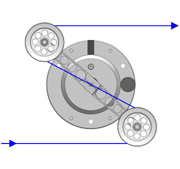

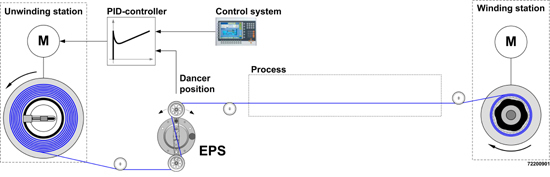

Functionality using the example of a typical unwinding process:

At the unwinder a motor-driven chuck supports the material roll.

The following process needs material feeding with process-specific dynamic and well-defined tension.

EPS serves as link between unwinder and process.

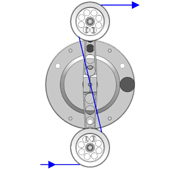

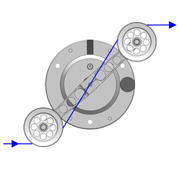

- The material is guided S-shaped over the dancer pulleys.

- A torque, which acts on the dancer, is generated electropneumatically.

- Tension Fz is proportional to the upcoming torque.

- The actual rotation angle of the dancer is output as electric signal.

- The dancer is in position control.

Material accumulator

Additionally EPS functions as an accumulator.

It can dispense or receive the material depending on the dancer position.