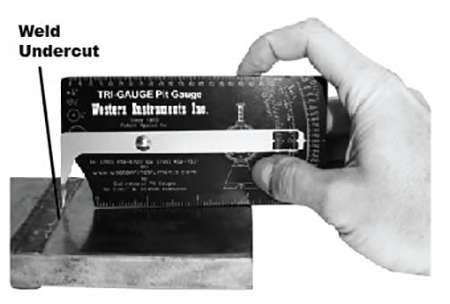

- Mechanical Lever Pit Gauge with Metric and Imperial Scales

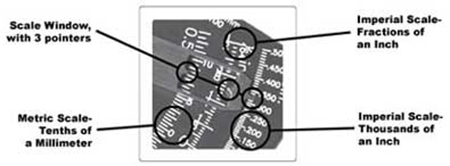

- Range/Resolution: +/-13mm (0.500") / 0.5mm (0.010")

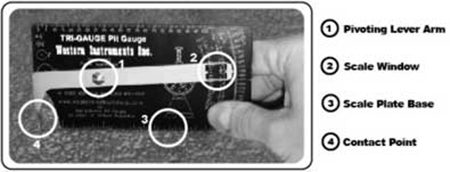

- Tri-Gauge® XM Lever Type Pit & Welding Gauge Part No. N88L-1

- Includes Manufacturer's Certificate

When the Junior Tri-Gauge® is manufactured a Skilled Technician Zeroed the Contact Point after the Offset Correction was induced into the Lever Arm. The Contact Point can become worn, damaged, or the Offset Correction® can be damaged. Any Zero Offset can become a hindrance to the operator, so it may be desirable to Zero the Contact Point.

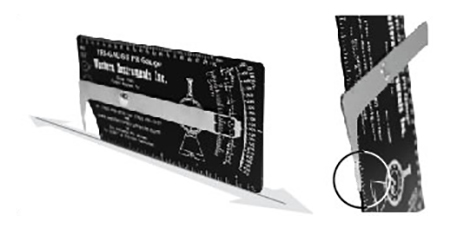

This Standardization can be performed by Western Instruments or you can attempt it yourself. If you attempt it yourself, you will need a small Ball Peen Hammer, an Anvil (or heavy plate), a Flat Plate, and a fine 6" file. You will need to determine if the Contact Point is too long or is too short. If the Contact Point is too short, it is placed on the Anvil, and the Hammer is used to Stretch the end by lightly taping the Contact Point. After each tap the Junior Tri-Gauge® should be checked against the Flat Plate. If the Contact Point is too long, or you have stretched it too much, the Tip is lightly filed from the beveled or inner side (adjacent to the Scale Plate)

| Item | Description | Price | ||

|---|---|---|---|---|

N88L-2 | Junior Tri-Gauge Pit & Welding Gauge, Range +/-3mm (0.100in) | $218.00 |