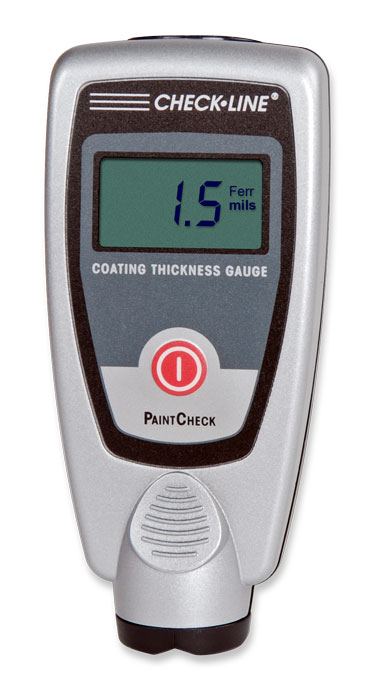

PaintCheck provides fast, non-destructive paint and coating thickness measurements on steel and aluminum (non-ferrous) metals. It is intended for use by car dealerships, auto body shops , insurance adjusters and similar users who only need a simple, one-handed basic gauge. The resolution is limited to 0.5 mils (5 µm) and should not be confused with our other "precision" gauges as this is adequate for basic thickness "checks".

Simply place the gauge on the surface to be tested. An accurate thickness reading appears almost instantaneously on the large, easy-to-read display—without scratching or damaging the surface in any way.

PaintCheck automatically selects the optimum measuring method (magnetic induction or eddy-current). No calibration is required.

In addition, PaintCheck provides valuable information about the coating structure, such as paint top coats or body fillers. For example, if the measured thickness value is significantly greater than the expected paint thickness, this would indicate the use of filler material or repainting.

Speed, versatility and ease of use make PaintCheck a valuable tool for a wide range of paint inspection tasks. Especially the basic tasks, not requiring the highest possible resolution.

- 2 Year Warranty

- Large measuring range: 0 – 80 mils (0 – 2000 µm)

- Resolution of 0.5 mils (5 µm) is acceptable for a basic paint "checker", but is not suitable for precise coating thickness measurement

- User-selectable units: mils or microns (µm)

- Simple, one-key operation

- Measures on steel, aluminum and non-ferrous metals

- No calibration required

- NIST-Traceable Calibration Certificate OPTIONAL

| Minimum Radius for Convex Surfaces | Fe - 1.5" (37 mm)<br>NFe- 3.0" (75mm) | |

| Minimum Radius for Concave Surfaces | 4" (100mm) | |

| Minimum Headroom | 5" (125mm) | |

| Minimum Sample Diameter | 1.6" (40mm) | |

| Minimum Substrate Thickness - F | 30 mils (0.75mm) | |

| Minimum Substrate Thickness - NFe | 10 mils (0.25mm) |

| Range | Fe: 0 - 80.00 mils (0 - 2000 µm) NFe: 0 - 80.00 mils (0 - 2000 µm) |

| Accuracy | ±0.5 mils plus 5% of reading ±5 µm plus 5% of reading |

| Display | 4-digit alphanumeric, 0.4" (10mm) height |

| Minimum Measuring Area | 1.6" x 1.6" (40mm x 40mm) |

| Minimum Substrate Thickness | Fe: 30 mils (0.75mm) NFe: 10 mils (0.25mm) |

| Calibration | Factory calibration |

| Operating Temp. | 32 °F to 122 °F (0 °C to 50 °C ) |

| Surface Temp. | 5 °F to 140 °F (-15 °C to 60 °C ) |

| Battery Type | 2 AAA 1.5V |

| Dimensions | 4.3" x 2" x 1" (110 x 50 x 25mm) |

| Weight | 3.2 oz (90 g) |

| Protection Class | IP 52 (proof against dust and dripping water) |

| Standards | DIN, ISO, ASTM, BS |

| Warranty | 2 year |